LGMG’s New Mexico Factory Launches Production

On Dec. 7th Mexico local time, the opening ceremony of LGMG Mexico manufacturing basement was held in Nuevo León state, marking a major milestone in LGMG’s global expansion and reaffirming its overseas development strategy.

As LGMG MEWPs manufacturing base in Roots Industrial Park in Monterrey, Nuevo León state, Mexico, its’ inauguration will significantly boost LGMG’s integration into the North American market and further accelerate its global expansion process and step forward for LGMG in overseas manufacturing.

Governor of Nuevo León State Samuel García, Secretary of Economy Iván Rivas, Chairman of LGMG Mr. Yu Mengsheng and Vice General Manager Mr. Shi Yanyu along with representatives of customers, suppliers, and partners from the American region, attended the inauguration ceremony. Together, they witnessed a fresh start for LGMG in Mexico.

Adhering firmly to its international development strategy, LGMG offers product experiences, sales, training, maintenance support, spare parts supply, and remanufacturing. The group aims to continuously enhance user value and satisfaction so as to inject more vitality into its global product strategy.

From going abroad to integrating into local markets, LGMG’s internationalization journey reveals simultaneous efforts to achieve localized production while concurrently improving the cultivation of local talent, operations, and services. This approach precisely matches local market demands and comprehensively propels internationalization across various domains such as product portfolios, support systems, human resources, and marketing.

In the future, LGMG will firmly establish itself in both domestic and international ecosystems, aiming to “become an important international player in the industry” and continue making breakthroughs in its global expansion strategy.

LGMG brings new products to the ARA show

From February 18th to 21th, LGMG participated in the ARA Show, the most professional aerial work platforms event in America, showcasing our new and reliable products.

LGMG exhibits 6 models at this significant event, including the latest vertical mast lift M2030SE, scissor lift models S1932E, SS1532ER and SR3369D and two booms A45JE and T65J-H.

Notably, M2030SE makes its debut on this occasion, becoming a hit for the market. M2030SE is LGMG’s newest mast lift, with the max working height of 8 meters. This model can allow one people to work and be used both indoor and outdoor. It has self-leveling chain system, and each mast can rise and fall synchronously. Its deck can be extended to enlarge the working capacity.

S1932E is produced by our new factory in Mexico, ensuring the fast delivery and quick response in the North America.

The Mexico plant came into production in December, 2023, producing more models and selling products to different countries and regions worldwide.

LGMG will continue to renew and improve its products to match the local market.

LGMG Global Partner Conference was grandly held!

On August 26, 2023, with the theme of New Ecology, New Factory, New Journey!

LGMG Global Partner Conference on Smart Manufacturing & Construction and Digital Factory Commissioning Ceremony was grandly held in Jinan, Shandong Province, with more than 1,000 people from 60 countries around the world, as well as industry experts, leaders of associations, government leaders, and representatives of the media gathered to witness LGMG’s comprehensive new journey towards internationalization!

Under the tide of “Internet+” and intelligence and digitalization, LGMG has accelerated the breakthrough of key technologies and applications. Now, LGMG is making every effort to build a new type of digital factory as a benchmark, and joining hands with global ecological partners to creating two industry-leading digital ecosystems. An intelligent manufacturing ecosystem and an intelligent construction ecosystem.

At the global partner ecological conference, Wang Zhizhong, Chairman of Lingong Group gives a speech, in which he looked forward to the future development plan and pointed out the direction for the intelligent and internationalized development path of LGMG.

Nowadays, the new round of global manufacturing competition has been converted into the competition of intelligent manufacturing, and LGMG, based on standardization and automation, takes the leading role of product line and workshop as the breakthrough, and devotes itself to building the digital factory project, leading the new track of intelligent manufacturing with leading digitalization concepts and innovation strength.

It is worth mentioning that during this event, the domestic supply chain ecosystem centered in Jinan and the Americas supply chain ecosystem centered in Mexico were officially launched.

“We will take this opportunity to build two domestics + international ecospheres, accelerate the pace of global development, and truly move towards Internationalization under digital collaboration!” Yu Mengsheng, chairman of LGMG.

The future is promising. As a leading enterprise in the construction machinery industry, LGMG will always adheres to the concept of “reliability”, accelerate the digital transformation and intelligent upgrading, led by innovation, continue to provide global customers with more comprehensive solutions, and contribute to the high-quality development of the industry with vigorous strength!

A Big Move for LGMG in North America

LGMG North America has relocated to a new premise in Dallas, Texas, a big move for LGMG in this area.

The new office has officially started business recently, and it will be the new Headquarter of LGMG NA.

The new premises include a warehouse and a full training center in addition to the offices, and it will also be responsible for sales and products display in North American market.

The new office is close proximity to our new plant in Mexico, allowing better communication and convenient transportation, and providing a logistical advantage for parts and service supply to our customers.

Specifically, the new office is located at 4105 Live Oak Dr, Suite 100, The Colony, Texas 75056.

For more information, please mail us at: [email protected] or call us 833-288-5464.

LGMG Brings Multiple New Products to CONEXPO-CON/AGG

LGMG shows off 11 machines at 2023 CONEXPO-CON/AGG, held in La Vegas from March 14 to 18, with some new products to the US market.

CONEXPO-CON/AGG is the largest event for construction and machinery in North America, and it has been 3 years since the last one. The booth of LGMG covers an area of 785 square meters this year, 40% larger than that of 2020.

The products on display include vertical masts, boom lifts, and scissor lifts. All machines have been integrated with LGMG’s latest R&D results and manufacturing process in MEWPS, leading the industrial development in intelligence, electrification, digitalization and environmentally-friendliness, which are highly acclaimed by visitors on site.

The most highlighted products are the new electric scissor lifts, which are fitted with maintenance-free AC functional motor and AC Driver motor, and have a service life of over 5 years. The protection grade difference is IP67, featuring waterproof and dustproof. This is the first time for LGMG to introduce the AC scissors to the world market.

M2640JE(M0810JE) is the first mast model that LGMG introduces to the American market. The 10ft 6in (3.2m) jib offers a larger working range. It has a stowed length of 8ft 6in (2.6m) for easy transport. Zero tail-swing, compact design, and light weight make the machine easy to maneuver in tight spaces.

LGMG also displays its latest telescopic boom lifts which were launched in 2022, including the lithium battery powered models and diesel engine driven H-series models. All the new telescopic models use the 4W driving, 4W steering and full-time floating axels, offering higher efficiency and safety in all terrains. Max. 5° tilt angle of the chassis and 45% gradeability allow the wheels to conform to the ground when passing the hard, uneven terrain.

LGMG always puts the user experience at high priority, listens carefully to the voices from different customers, makes quick response to market demand, constantly improves the technology, and makes innovation to add value to the products, as a way to gain customers’ recognition and builds the reputation through practical action.

During the expo, a large quantity of customers visited LGMG’s booth, either for observing the machines, or showing interest in cooperation, or placing a purchasing order directly on site, proving the popularity and reliability of LGMG’s products.

LGMG Further Strengthens Cooperation with COBO

On March 15th 2023, a global strategic cooperation agreement was signed into effect between LGMG and COBO at CONEXPO-CON/AGG 2023, held in Las Vegas and the largest construction trade show in North America.

Mr Zhi Kaiyin, General Manager of LGMG, and Mr Stefano Scapin, COBO Chief Business Development Officer, together with other respective delegations from both sides attended the signing ceremony.

The cooperation aims to strengthen the bilateral business association, and further expands the business cooperation scope, said one of the executives.

LGMG and COBO started their cooperation in 2018. More recently, LGMG and COBO have strengthened their collaboration to expand the business scope.

The strategic agreement between LGMG and COBO is based on close communication, qualitative and technical solutions, and it is expected to broaden the scope of cooperation in China and abroad.

In October, 2022, Mr Kaiyin Zhi, led a delegation to visit COBO Headquarters located in the province of Brescia, Italy, where they were impressed by COBO’s technology, finished products.

During the visit, Mr Stefano Scapin emphasized the importance to keep strict control of certain processes such as the design, manufacturing and testing of electronic boards and finished products, so as to reduce the time to market and minimize risks caused by the most recent semiconductor crisis.

LGMG has made remarkable achievements, thanks to the support of the partners and friends all over the world. Facing the completely new global market, LGMG will continue to work closely with the global suppliers, adhere to the overseas operation strategy of localized talents, operation and service, precisely match the local market demand, accurately position its products, carry out localized and differentiated operation based on high-quality products and efficient services, to steadily expand its overseas business.

LGMG Brings New Products to the ARA Show

From 13 to 15 February 2023, LGMG took part in the ARA exhibition in New Orleans, LA. At this show, LGMG introduced its latest and new products S1932E, SR2669D, and the popular A45JE and T65J.

The new lead-acid battery-powered scissor lift S1932E has a maximum working height of 25ft 7in and a capacity of 510 lbs. It can be used both indoors and outdoors. The efficient electric drive system provides long-lasting performance.

This model is equipped with a swing-out component tray, which is easy for access and maintenance.

The key components such as joysticks, drive motors, motor controllers, and chargers are highly interchangeable with existing models on the market, making it easy to replace, to save costs for daily operation and maintenance.

Besides the S1932E, new-fuel rough terrain scissor lift SR2669D was also presented at the show.

SR2669D can be driven by gasoline or LPG. The dual-fuel drive technology features low cost, simple operation, safety, reliability, and convenience.

This model has a max. working height of 31ft 10in and a platform capacity of 1499 lbs which can allow 4 people to work at the same time both indoors and outdoors.

LGMG A45JE and T65J were also popular on the show.

LGMG A45JE has a max. working height of 51ft10in and a platform capacity of 510 lbs. This model is one of the most popular articulating boom lifts on the market. It delivers comfortable operation, precise positioning and exceptional productivity on job sites.

T65J offers a working height of 71ft 2in and a capacity of 551 lbs. With oscillating axles and four-wheel drive, the machine can operate on the roughest ground and complete the task on time.

This ARA show was a great success, at which we made many new friends and met a lot of familiar old friends too. LGMG would like to thank all those who supported us and came to our booth. In the future, we will continue our philosophy of Reliability in Action, keep strengthening our research and development to meet the needs of more customers.

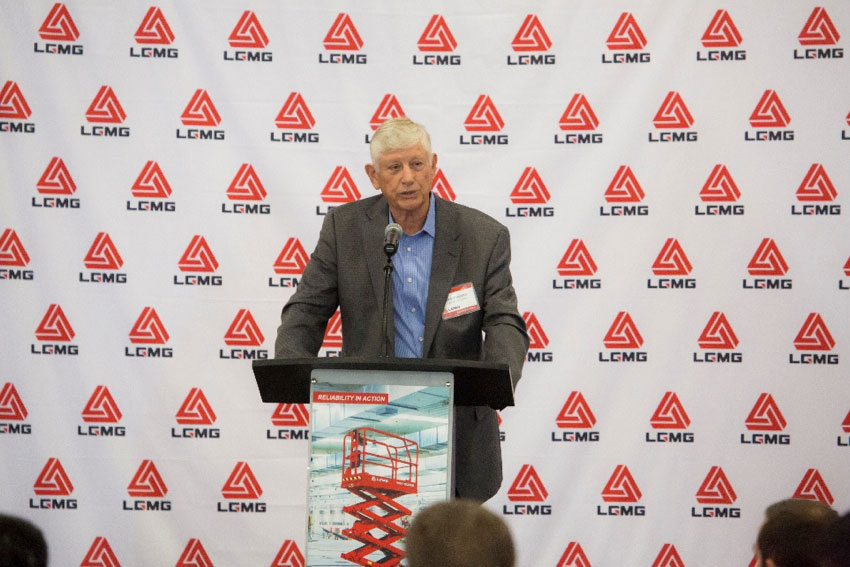

LGMG North America Inc. Hosts Grand Opening While Looking to the Future

“…the right time, the right company, and the right people to partner with” – CEO Craig Paylor

Chambersburg, PA, June 25, 2019 – Last week, LGMG North America Inc. (LGMG NA) hosted heavy equipment industry leaders at their Chambersburg facility to officially announce their presence in the North American aerial lift market. LGMG NA is the North American branch of Lingong Group Jinan Heavy Machinery Co LTD., and intends to transform the aerial lift market with excellent ANSI approved products at the best prices. Speakers at the ceremony included Kaiyin Zhi, the General Manager Lingong Group Jinan Heavy Machinery Co LTD., LGMG NA Chairman Yanyu Shi, LGMG NA CEO Craig Paylor, Lew Hudson Sales CEO Lew Hudson, Dana Off-Highway America Sales Director Garry Francis, and Danfoss Power Solutions Sales Director Ian MacLeod. Pat DeVitto, President of Cardinal Sales and Rusty Kaylor VP Sales – Southeast LGMG North America was also in attendance. Craig Paylor and Kaiyin Zhi cut the ribbon on the grand opening together signifying the unity between the North American branch and the parent company.

Guests were taken on a tour of the facility after the remarks and ribbon cutting to gain a greater understanding of LGMG NA. The first LGMG NA branch was opened in the world’s largest aerial work platform market which has put it in a prime position for current and future customers. The LGMG NA Chambersburg location covers an area of 60,000 square feet with more than 50,000 square feet of warehouse. The stock of scissor lifts exceeds 1,000 units and most lifts can be shipped to a customer within 24 hours. LGMG NA also prioritizes its parts service in order to serve customers effectively and efficiently by having a large stock of spare parts located in all of our facilities that can be delivered within 24 hours. There is also a plan to add more as the product lines grow and the distribution demand increases. LGMG NA is extremely focused on all aspects of moving product into distribution including sales, leasing, rentals, and trade-ins as the new standards become the standards. LGMG machines are leading this as they already meet the new requirements.

From Left: Sean Gao (CFO – LGMG North America), Dan Bishop (COO – LGMG North America), Craig Paylor (CEO – LGMG North America), Kaiyin Zhi (General Manager – LGMG), Yanyu Shi (Chairman – LGMG North America), Yuxing Song (AWP Marketing Division Export Department Head – LGMG)

Room to Grow

Chinese manufacturer LGMG brings scissor lift line to North America with goal of targeting independent rental companies.

When Chinese heavy equipment manufacturer LGMG looked at the North American aerial lift market, the company saw opportunity.

Small to mid-size independent rental companies had needs that the current market wasn’t meeting, and there was room for additional players in the space to provide solutions, according to LGMG, which stands for Lingong Group Jinan Heavy Machinery, a subsidiary of Lingong Machinery Group.

With the assistance of a pair of industry veterans that know this market and more than four decades of manufacturing experience, LGMG made its official North American debut at the 2019 ARA Show in Anaheim, Calif., launching an initial line of scissor lifts.

Founded in 1972, Lingong Machinery Group is one of the largest construction equipment manufacturers in China, says Sean Gao, director of finance for LGMG North America, which is based in Chambersburg, Pa. About four years ago, the company started making MEWPs, and last year, the company sold about 8,000 units in China, Gao says. They also have a base in Europe.

But the U.S. is the key, growing market the company is targeting, says Gao, who graduated from Ohio State University and is relocating from Toronto to Pennsylvania. He also has a personal connection to LGMG, with his father serving as a Lingong Machinery Group director.

The company enlisted Craig Paylor, the former president of JLG Industries who saw the OEM grow from a $30-million business to a $3.1 billion during his more than 30 years there, and Rusty Kaylor, who has over 40 years of rental company experience, to help them get their start here. Both Paylor and Kaylor, who have known each other for about 30 years, say that independent rental companies are in need of quality, cost-competitive MEWP options for their fleets, and that is what LGMG brings to the table.

“There’s a niche out there for small independent rental guys who need some numbers that will get them in the ballgame again,” says Kaylor, who was the CEO of Alliance Rental north of Atlanta prior to its sale to Ahern in 2013 and came out of retirement to help launch LGMG in the U.S. “The guys that are getting the great prices are the big companies, and I can understand why the big manufacturers give the big rental companies a really good price. We’re not trying to match that price. We’re just trying to get the small independent guys who want to buy half a dozen or a dozen—we want them to be able to get a number that they can live with in this marketplace.”

A Competitive Option

Paylor says LGMG’s scissor lift line, which is compliant with the new ANSI and CSA standards, offers a variety of options, from the self-propelled, low-level SS series, which starts with a platform height of 12’30”, to the electric or hydraulic AS series, which range in platform height from 19 ft. to 45 ft.

“Each model has a different price point,” Paylor says. “All the price points are very competitive and allow people to grow their businesses by buying a quality product with good service and support.”

Some of the lifts’ differentiating characteristics when it comes to quality is their smooth deck extension, universal drive controller, larger scissor arms for increased stability, easy-to-access serviceability, water-resistant powder-coated finish, and mostly American components with Trojan batteries, says Dan Bishop, the operations manager for LGMG

This is where drawing from their experience both on the manufacturing and rental side helps them understand what features are important to the independent rental customer in LGMG’s sights, such as an advanced battery charger that can bring the machine back from a dead state to full charge without external help, Kaylor says.

“There’s a lot of small things that add up to big differences, especially if you’ve been in the industry and you’ve dealt with it on a day-to-day basis,” he says.

LGMG maintains consistency over the line through a lean manufacturing process at their two plants in China, which employ about 4,000 people according to Gao, with the ability to make about 100 units a day.

The company has set up two U.S. parts and distribution centers, with one at its Pennsylvania headquarters, and the other in Ducktown, Tenn., with several hundred units in stock to initially focus on sales and service in the East. They have hired a team of about 10, and Gao says they’re aiming to bring on about 20 more employees by year’s end. Paylor says the goal will then be to expand and cover the rest of North America, setting up additional distribution centers in the Midwest and Texas next.

But Paylor says the plan is to grow strategically—LGMG has no interest in selling product they can’t service, he says, noting those are two factors why there was opportunity in the market in the first place.

“The way I like to look at it is we don’t want to over-promise and under-deliver,” he says. “If we can’t deliver or service the machines in a timely manner, we’re not going to promise that we can.”

In fact, Paylor says at the show, LGMG had to turn away some customers they wouldn’t be able to service adequately at this point. The company already has the interest to sell more models—including a rough terrain scissor lift line it plans to introduce in the coming months—when it is ready.

“Everybody that I’ve spoken to … they appreciated the quality of the product and the price point offered for the product; and we’ve had a lot of attention,” he says.

The management team of LGMG North America includes industry veterans Craig Paylor, left, and Rusty Kaylor, who are joined by Sean Gao, director of finance, and Dan Bishop, director of operations

A Solid Reputation

In addition to LGMG’s goal of offering a solution to a segment of the market, Gao says the company is also here in North America to learn as the brand builds on its reputation of lifting material to lifting people—and it is eager to hear feedback from customers.

“It’s also important to note that we’re not trying to be anything right now,” Kaylor says. “We’re just trying to get our products out in the field—let our customers see that it’s a good quality product—and enhance their opinions of a Chinese-made product that’s being managed by a North American veteran management team.”

As other Chinese aerial lift manufacturers look to enter the North American market in the near future, LGMG can count its veteran team as another distinct benefit to have in its corner.

Kaylor says he was enjoying his view from his porch during his retirement, when the product basically compelled him to encourage his friend Paylor to go for another round.

“We’ve been very careful about not tarnishing the last 40 years,” Kaylor says. “With the product that’s here, we feel that it will just enhance the last 40 years … when it’s time to go back to the porch.”

Focusing on North America

Chinese manufacturer LGMG has entered the North American market with a plan to capture small and midsized rental business. Lindsey Anderson speaks with the company’s director, Rusty Kaylor, about opportunities and ambitions.

In late 2017, Chinese construction manufacturer LGMG told ALH it was planning a major global expansion of its access products, starting with its sights set on Europe followed by a move into the North American marketplace.

Fast-forward two years and the company’s vision has materialized. In January 2019, LGMG opened its first North American facility in Chambersburg, PA with a goal to attract small and midsized independent rental companies. The company currently offers a range of rough terrain scissor and boom lifts and has already sold several hundred scissors to the marketplace with a goal of several thousand for the coming year, according to Rusty Kaylor, LGMG North America’s VP sales – Southeast.

“The North American market is in need of a quality aerial lift product that not only has a price point that makes the small to midsized rental companies competitive to the top 10 rental companies, but also has the back up and support they have to have to be competitive,” Kaylor says. “We can provide both and intend to fill this market gap that other manufactures are ignoring.”

LGMG is based in Chambersburg, PA and chose Pennsylvania as its home base because the State “has long been known as the birthplace of the aerial lift industry,” Kaylor notes. It is also the lifelong home of LGMG North America’s CEO, Craig Paylor, who was instrumental in making the access industry what it is today.

Wealth of experience

Paylor spent more than 30 years at JLG Industries, Inc., where he played a key role in developing the company from a $40 million privately held business to a publicly traded global corporation with sales approaching $3 billion prior to the Oshkosh acquisition in 2006. He retired in 2010 after serving as JLG’s president since 2007. Kaylor is also a veteran of the access and rental industries, having first entered the industry in 1977. He was instrumental in the development of one of the first electric drive scissor lifts, the ReachLift, and operated a number of rental outfits from 1983 to 2015.

The two bring a wealth of experience and knowledge to the new North American venture and plan to use their wisdom and know-how to educate the market on LGMG products.

“We offer a top-quality product with an expanding product line designed and engineered for the North American market at a competitive price that is being managed by an experienced team that has been involved with every facet of the industry for decades,” Kaylor notes. “The big difference here is the quality of the product along with the expertise of the management team; we understand this market better than our competitors because we have been in the rental business and the manufacturing industry in a big way for a long time.”

Foundation

LGMG originated in 1972 and is located in Jinan, Shandong Province, China. It consists of three core companies – Shandong Lingong Construction Machinery Co., Ltd (SDLG), Lingog Group Jinan Heavy Machinery Co., Ltd (LGMG) and Lingog Special Machinery Co., Ltd. – and is affiliated with 16 companies. Its business segments include construction machinery, mining machinery, mobile elevated work platforms, special machinery and component manufacturing.

The company has two joint ventures, one with Sandvik, as part of its LGMRT mining and rock technologies segment, and the other with Volvo, representing the entire SDLG subsidiary. Under the two arrangements, Sandvik owns 65 percent, while Volvo has 70 percent ownership of the respective ventures.

The company started producing loaders 45 years ago with the medium range 3-ton and 5-ton segment making up 80 percent of the business. In the large sector the company already has a 40-ton truck and now has drilling rigs thanks to its partnership with Sandvik. Then, in the small segment, there are the 3.5-ton to 15-ton excavators and now MEWPs.

Products by the numbers

The plan is to offer the customer a full set of products. In 2016, LGMG said 27,000 MEWPs were produced in China across the eight biggest manufacturers manufacturing in the country.

By the end of 2017, that number reached 40,000 with LGMG having produced 4 percent of that volume, according to the company. LGMG’s target is to reach a minimum of 10 percent of the total output figure.

Making a move into North America increases the company’s footprint and customer base, but as many know, entering the industry here can be somewhat of a challenge; parts, service and distribution are key to running a smooth and successful business.

Presently, LGMG North America has parts and service locations that are fully operational and stocked in Atlanta, Houston, Chambersburg, PA and Ducktown, TN.

“It is our plan to strategically locate parts, service and machine sales location throughout North America,” Kaylor says. “Our engineering center located in Chambersburg, PA will be fully operational in the near future. We are currently evaluating products for us to manufacture here in the USA.”

Kaylor says there is definitely room here for LGMG products.

“Our products have a high quality due to our attention to the heavy wear parts of the machines; arms, cylinders, pothole protection, door hinges and wiring harnesses as well as the major components are all sized and tested for a long machine lifetime of quality use,” he notes. “We have learned from customers what not to do, because it has been done before and did not work.”

Partnerships growing for LGMG

In May, LGMG announced a renewed partnership with Germany-based PB Lift. The Chinese manufacturer produces PB’s Eco line of scissor lifts, and now its PB’s turn to offer its services and experience in helping to grow LGMG sales in Europe.

As Ares Song, international sales manager at LGMG said, PB’s role is essentially as a high-level consultant as LGMG seeks to approach the European market in the correct manner. “We do not want to damage the market by putting low priced machines into it. It’s important that all suppliers in the chain benefit from the market.”

Part of LGMG’s strategy is to make products specifically for the European market and PB will provide ideas to help it do this.

“We want to be up and running but in the proper European way.”

LGMG is ambitious and, as reported by sister publication Access International last year, the company set up a European division in 2018, including a depot and service center in the Netherlands. It is also bringing long-standing access professionals on board in the continent,

including most recently Ronan Mac Lennan as sales manager for Great Britain, Ireland, Scandinavia and European key accounts and Erik de Bruijn, as technical and product support manager. Both were at Bauma and have recently moved over from GMG. Between them, they have decades of experience in the access industry.

They join Hans Aarse, senior adviser, previously with IPAF, who came out of retirement to work with the company, and Maurice Jassies, sales manager Benelux, both taking up their positions earlier this year at LGMG Europe, which was launched in September 2018.