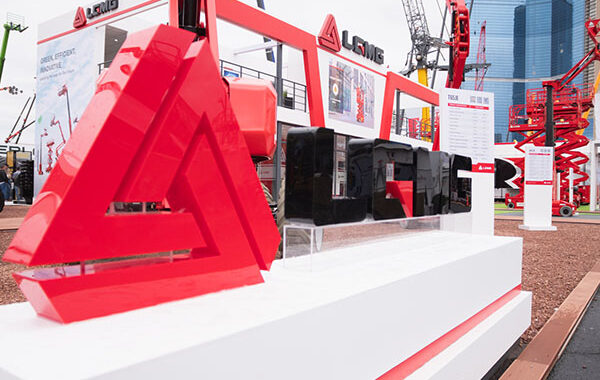

LGMG shows off 11 machines at 2023 CONEXPO-CON/AGG, held in La Vegas from March 14 to 18, with some new products to the US market.

CONEXPO-CON/AGG is the largest event for construction and machinery in North America, and it has been 3 years since the last one. The booth of LGMG covers an area of 785 square meters this year, 40% larger than that of 2020.

The products on display include vertical masts, boom lifts, and scissor lifts. All machines have been integrated with LGMG’s latest R&D results and manufacturing process in MEWPS, leading the industrial development in intelligence, electrification, digitalization and environmentally-friendliness, which are highly acclaimed by visitors on site.

The most highlighted products are the new electric scissor lifts, which are fitted with maintenance-free AC functional motor and AC Driver motor, and have a service life of over 5 years. The protection grade difference is IP67, featuring waterproof and dustproof. This is the first time for LGMG to introduce the AC scissors to the world market.

M2640JE(M0810JE) is the first mast model that LGMG introduces to the American market. The 10ft 6in (3.2m) jib offers a larger working range. It has a stowed length of 8ft 6in (2.6m) for easy transport. Zero tail-swing, compact design, and light weight make the machine easy to maneuver in tight spaces.

LGMG also displays its latest telescopic boom lifts which were launched in 2022, including the lithium battery powered models and diesel engine driven H-series models. All the new telescopic models use the 4W driving, 4W steering and full-time floating axels, offering higher efficiency and safety in all terrains. Max. 5° tilt angle of the chassis and 45% gradeability allow the wheels to conform to the ground when passing the hard, uneven terrain.

LGMG always puts the user experience at high priority, listens carefully to the voices from different customers, makes quick response to market demand, constantly improves the technology, and makes innovation to add value to the products, as a way to gain customers’ recognition and builds the reputation through practical action.

During the expo, a large quantity of customers visited LGMG’s booth, either for observing the machines, or showing interest in cooperation, or placing a purchasing order directly on site, proving the popularity and reliability of LGMG’s products.